Binocular inclined at 45’ Rotatable 360’

- Achromatic objectives 4x,10x,40x, (SL) 100xoil(SL)

- Fine Adjustment : 0-180 knob For slow Motion & Highly Sensitive Fine Motion

- W F 10x Eye Piece Pair

- Co-axial Mechanical Stage

- Quadruple Revolving Nose Piece with Accurate Centring and Positive Click Stop

- In built High Resolution ¼” colour CCD Camera

- Simultaneous Multi-Model Display : Through Eye Piece Through Direct Video Display

Note : Our Microscope With CCD Camera Unit Can Be Directly Attached To T.V. Through A.V. Leads For Direct Observation On T.V. Screen

TECHNICAL DATA OF IMAGINE DEVICE

POWER SOURCE -Dc 12v +_ 10%

IMAGE DEVICE – ¼” COLOR CCD IMAGE SENSOR NTSC /PAL Output

RESOLUTION -380 Tv Line/720X576 Pixels (PAL) 720X480 Pixels (NTSC)

LIGHT SENSITIVITY –0.5 Lux (F 2.0” k)

INTERFACE –Composite Video Av Mode 7500 Ohm/Optical USB Ver 2.0

WHITE BALANCE-Auto

ELECTRONICS SHUTTER SPEED -1/55 1-100000 SEC.

CURRENT COMPOSITION-12ma

SYSTEM REQUIREMENTS –200Mhz (Pentium 2) Or Higher 64 Mb RAM or More , 15” Or Above Monitor 100 MB or Above Hard disk Space CD-ROM ,USB Port Printer (for Printer Report)

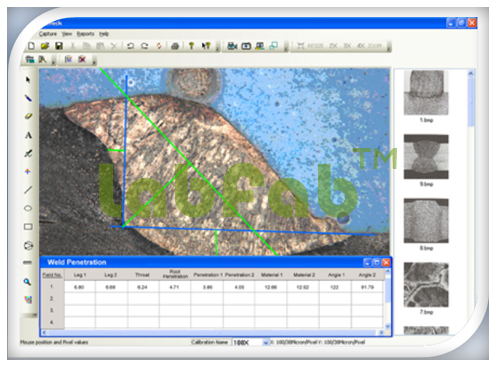

Optical Accessories :- Tv Tuner Card, Image Analysis Software